As the project has reached a point where it going to need a place to be built in, we decided to build a modular workshop now. The design below was drawn up first. The idea was that it can be spit

down into four sections to be transported to a new site Planning on moving to a better site in the next couple of years. The design is built around a freestanding central truss across the middle of the workshop to which the four section of the workshop are bolted. Each section of the workshop includes a floor section side and end wall and roof (when the sections are moved these will have to be supported with braces).

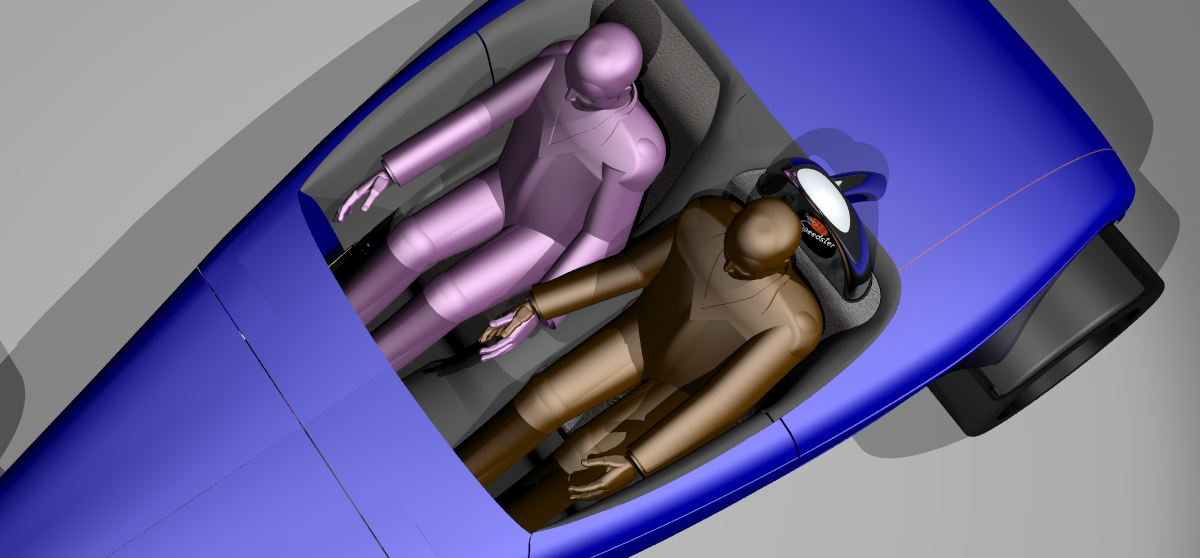

It will be another month or so before the interior of the workshop is completed so a little longer before we get back to the roadster. Looking forward to building up the basic frame and seating to test that it is comfortable before designing to much more, may be the steering wheel mounting need to be designed first. The car has got to be drive-able, so we wanted to do some full scale testing to be sure…..hence the workshop.